Cfr octane engines compression ratio displayed as the cylinder height values is a significant variable in relation to knock in internal combustion engines. It is a basic parameter for the knock testing methods.

The cfr octane engines cylinder assembly provides a means to change compression ratio by moving the cylinder up or down with respect to the crankcase. As a convenient alternative to determination of the actual compression radio, the vertical position of the cylinder can be measured. And it provides an indication that is proportional to compression ratio.

Two approaches to indicating the cylinder height are applicable: C. R. Digital Counter and Dial Indicator. (More details about their applications, please see “Octane Engines Digital Counter and Dial Indicator Applications” in our blog.)

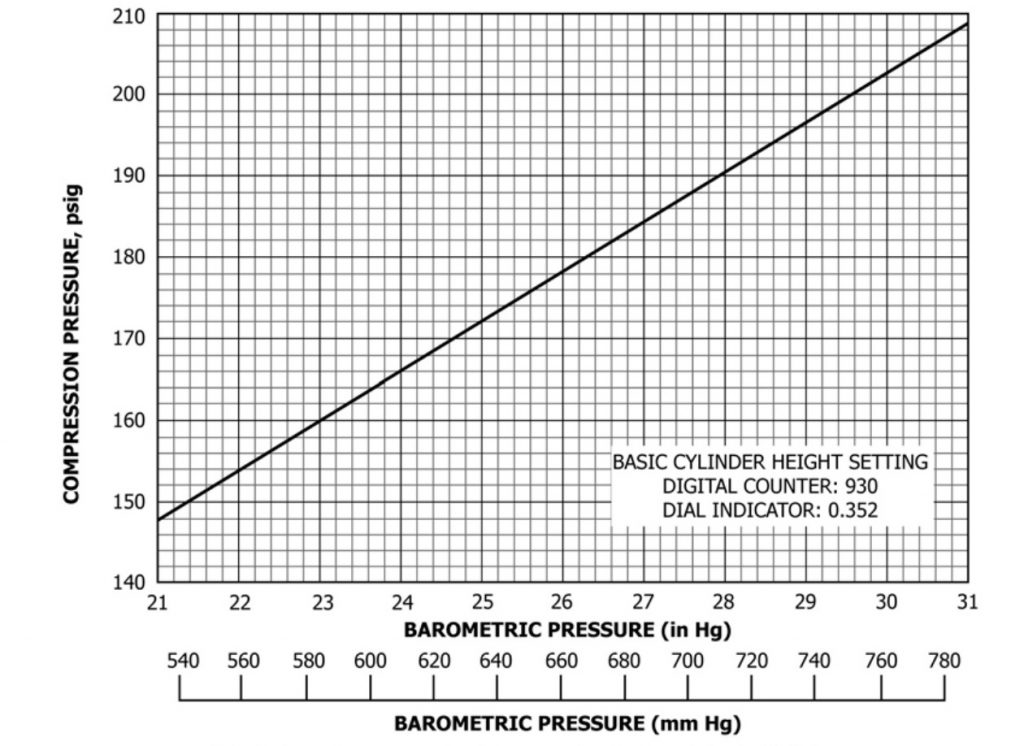

The cylinder height measurement instrument must be indexed to a standardized value after every top overhaul or maintenance of cfr octane engines. The basic cylinder height setting can be achieved by adjusting the cylinder position until a specified compression pressure is produced dependent on the prevailing barometric pressure.

Above Figure is utilized to indicate the compression pressure. The pressure must be produced at standard operating conditions with the octane engines motoring. The cylinder height instrument is then set to the uncompensated basic value. For C.R. digital counter assemblies, the basic digital counter reading is 930. For dial indicator assemblies, the basic dial indicator reading is 0.352 in.

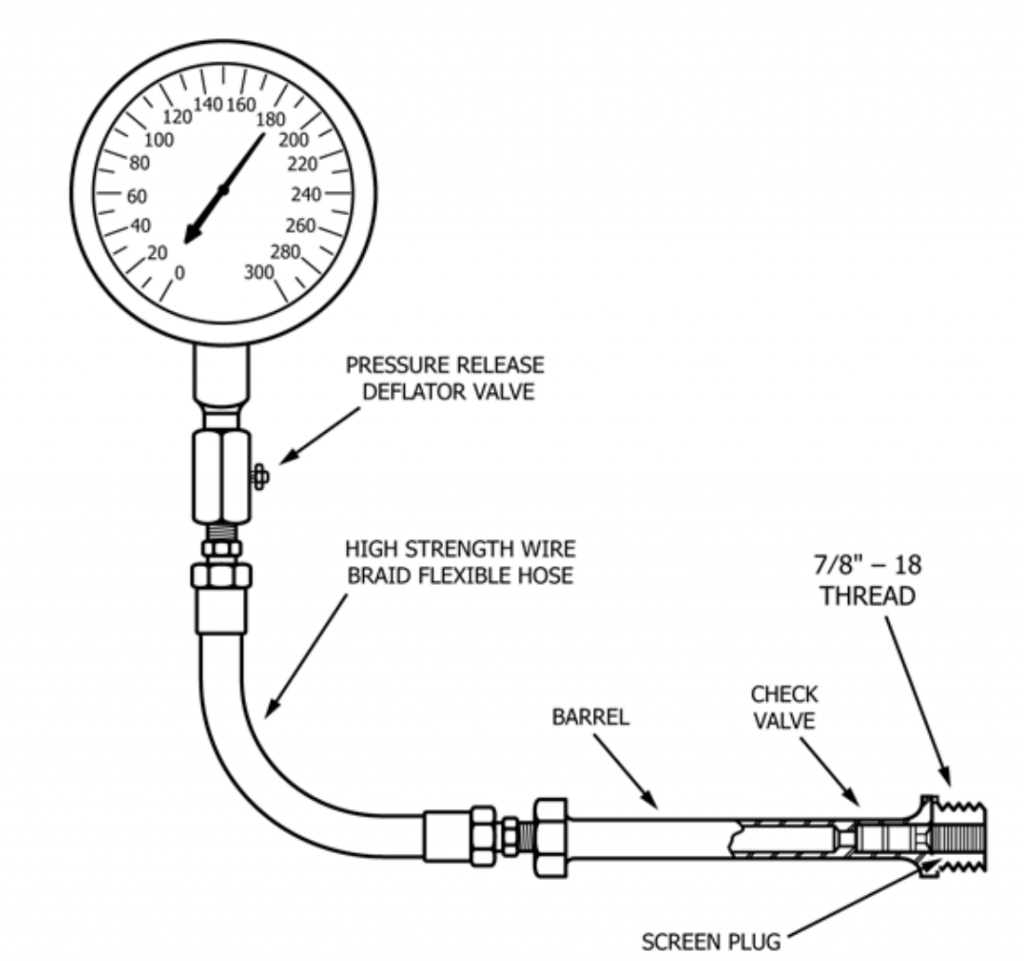

According to ASTM D2699 and ASTM D2700 standards test methods, the cfr octane engines cylinder height basic setting shall be performed using the compression pressure gage assembly. The pressure gage measures the compression pressure. For more details about how to set the basic cylinder height. Please see our blog “Octane Rating Engine: Basic Cylinder Height Setting Steps”.