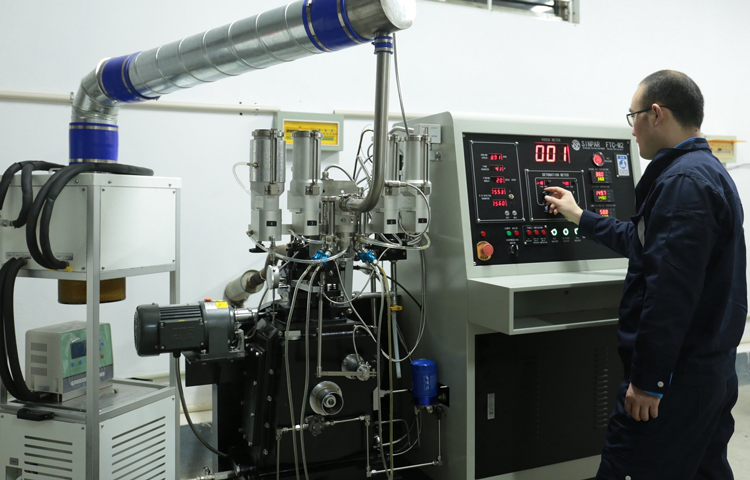

SINPAR TESTING CENTER

Internal Testing is an important means for us to analyze, evaluate, and verify the quality and reliability of products. SINPAR Testing Center provides a complete range of quality & performance tests for each octane engine by ASTM standard to ensure its excellent performance.

Through the statistical analysis of the test results, it is verified whether the mechanical properties, technical parameters, and octane rating stability, accuracy, repeatability, reproducibility of octane engine meet the requirements of ASTM D2699(ISO 5164) and ASTM D2700(ISO 5163).

PURPOSE & PRINCIPLE OF PRODUCT TESTING

1. A CONSENSUS:

In order for the end user to be satisfied with the product, it is necessary to ensure that the functional performance of the product meets the user’s needs. The only way to verify that product functionality meets user requirements is continuous and effective testing.

2. TWO POINTS OF VIEW:

1) From the user’s point of view, it is hoped that the test can fully expose the defects in product, in order to decide whether to purchase.

2) From the developer’s point of view, it is hoped that the test will show that the product does not have defects, and the user’s needs have been fully and correctly implemented.

3. TREE QUESTIONS:

1) From a design perspective, is there a design flaw? Testing Center can give an answer.

2) From an application perspective, does the user accept and like the operation method? Testing Center can give an answer.

3) From an implementation perspective, does the product have achieved the expected test results? Testing Center can give an answer.