Before operating an octane testing equipment, the operator must be knowledgeable about the fuel octane testing engine and the most recent versions of ASTM D2699 (Standard Test Method for Research Octane Number of Spark-Ignition Engine Fuel), and ASTM D2700 (Standard Test Method for Motor Octane Number of Spark-Ignition Engine Fuel). The prestart inspections shall be performed strictly. Failure to operate the octane testing equipment properly may result in equipment damage.

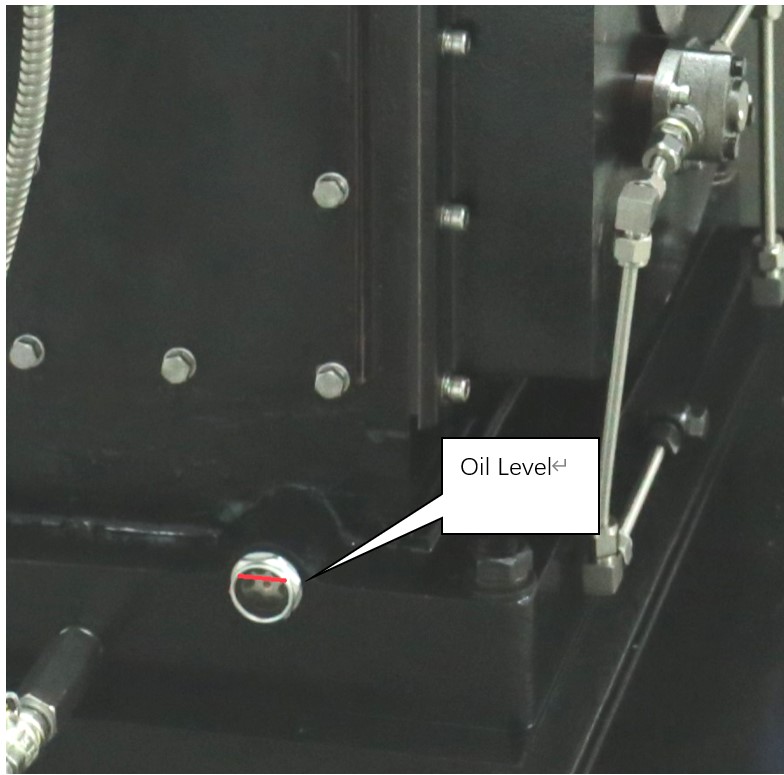

1. Check the octane testing engine crankcase oil level as viewed in the sight glass. The sight glass is on the lower right side of the crankcase. The level should be near the top of the sight glass with the engine stopped and cold (see below Figure).

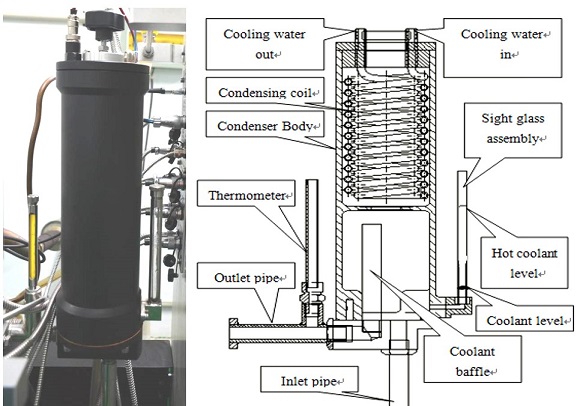

2. Check the jacket coolant level, as viewed in the condenser assembly sight glass. Ensure that the coolant liquid is approximately 5mm above the bottom of the sight glass (see below Figure).

NOTE: When the octane testing engine is running and at temperature equilibrium, the jacket coolant will expand and the level in the condenser sight glass should be at the 100mm above the bottom of the sight glass.

3. Observe the C.R. digital counter assembly reading or dial indicator, and if necessary, raise the cylinder height (lower the C.R.). So that knock does not occur when the engine is first started.

4. Check that the ignition switch on the instrument console panel is OFF.

5. Using flywheel handle inserted through the engine crankshaft guard, manually turn the octane testing engine in a clockwise direction through 2 or 3 complete revolutions to ensure that there is no interference inside the engine and that all parts move freely.

6. Turn on the main valve of the cooling water system to supply cooling water to the coolant condenser. Observe that cooling water is being discharged at the system drain.

7. Select a warm-up fuel, and fill one of the carburetor bowls to near the top of the carburetor bowl sight glass. Open and close the sight glass drain valve at least three times to purge any air bubbles from the sight glass and associated tubing.

8. Position the fuel selector valve between the mark that is applicable to the carburetor bowl that has been filled and the adjacent mark. So that fuel will not enter the carburetor vertical jet when the octane testing engine equipment is initially started.