According ASTM octane/cetane test methods, the standardization and reference fuel blending shall be performed for octane/cetane test. The most blends prepared in an octane test laboratory are normal PRF (primary reference fuel) and TSF (toluene standardization fuel) blends. It is considered good practice to make blends of reference fuels as required rather than to prepare and store them in glass bottles ahead of time.

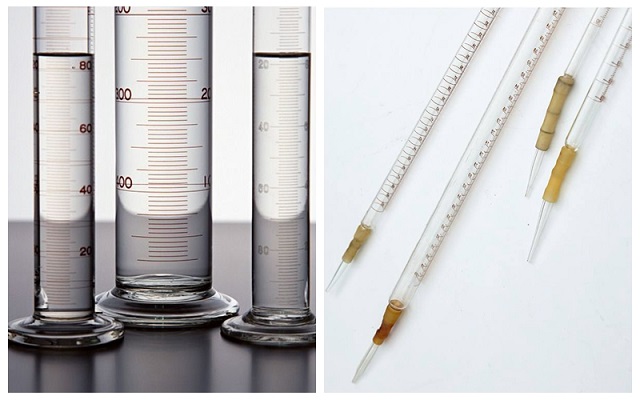

For most octane/cetane test engines, the reference fuel blending is performed manually using measuring glass cylinders or glass burettes in the ASTM standard.

Manual blending by volume using measuring cylinders or glass burettes seems to be the cheapest solution to prepare reference fuels. However, it has several disadvantages:

The tables in the ASTM standard for reference fuels blending are given in volume percent. Taking into consideration the densities of the two components a calculated amount of each can be added to a container placed on an electronic balance.

The measurement will be more accurate and no special care need be taken regarding the temperature of the components.

The accuracy of the blend will only depend on the short-term stability and linearity of the balance, which is better than +/-0.1 g for even the most modest electronic laboratory balances.

Automatic Reference Fuel Blending by weight uses a computer to read the electronic balance, to control the whole blending process.

After the required volume and octane/cetane number is given by the operator, the computer will make the calculations and control the blending process until the reference fuel is made.

The results can be stored in a database and certificates can be printed for all blends.

The automatic blending is very comfortable and needs no special attention from the operator.

The blends will be highly accurate because all possible human error is eliminated.

SINPAR Automatic Reference Fuel Blending Unit used in conjunction with octane/cetane test engines can obviously improve the accuracy and stability of octane/cetane test results, and can save the operator a lot of time.