Octane engine motor is started by applying three phase electrical power to the Multi-Speed induction motor to bring the octane motor and engine up to the applicable synchronous speed. In this mode of operation, without engine combustion taking place, the octane motor unit is commonly said to be “Start”. When fuel is introduced to the engine and the operating conditions are adjusted to cause combustion to take place, the octane testing unit is commonly said to be “Firing “.

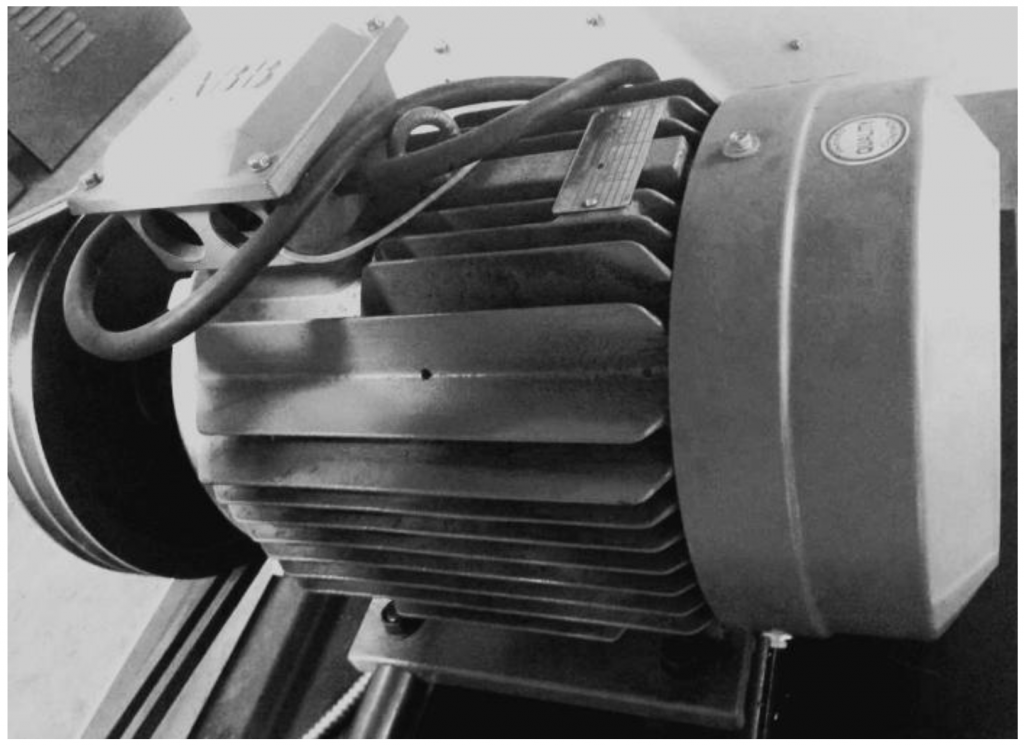

The Multi-Speed induction motor connects to three phase AC power. It drives the octane engine for starting purposes and is driven by the engine to absorb engine power and maintain constant speed during the rating application of the octane engine.

The Multi-Speed induction electrical motor parameters are as follows:

◼ 50/60Hz 380VAC 1450 r/min 5.5 KW

◼ 50/60Hz 380VAC 960 r/min 4 KW

Input power circuits are equipped overload protection switch that is normally closed but opens when the electrical motor case current exceeds 12A. This switch is used in the start-stop circuitry to provide automatic unit shutdown if the octane motor overload.

Two “B” size, matched length, V-belts connect the engine flywheel to the motor pulley. The belts connecting the flywheel to the absorption motor shall be tightened.

– Turn off all the electrical power circuits to the octane engine unit.

– Check the condition and tension of the drive belts.

– Replace belts as required and adjust the motor position to achieve proper belt tension.

– Remove dust and dirt from the end bell openings using low pressure compressed air.

Multi-Speed induction octane engine motor requires very little maintenance. If replacement of a Multi-Speed induction motor is required, it shall be performed by a qualified electrical person or trained person.