The RON/MON octane engine cylinder height, a measure of compression ratio, has a significant effect on fuels and their knocking characteristic. Each fuel has a critical compression ratio at which knock begins to occur. As compression ratio is increased above this critical threshold, the degree of knock increases.

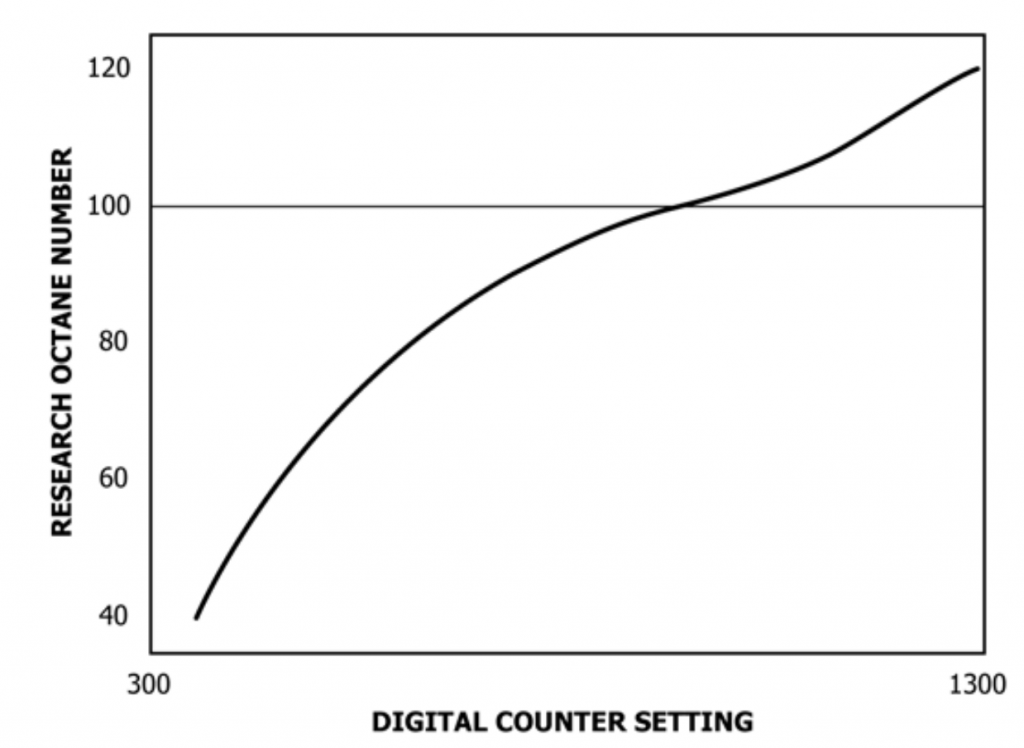

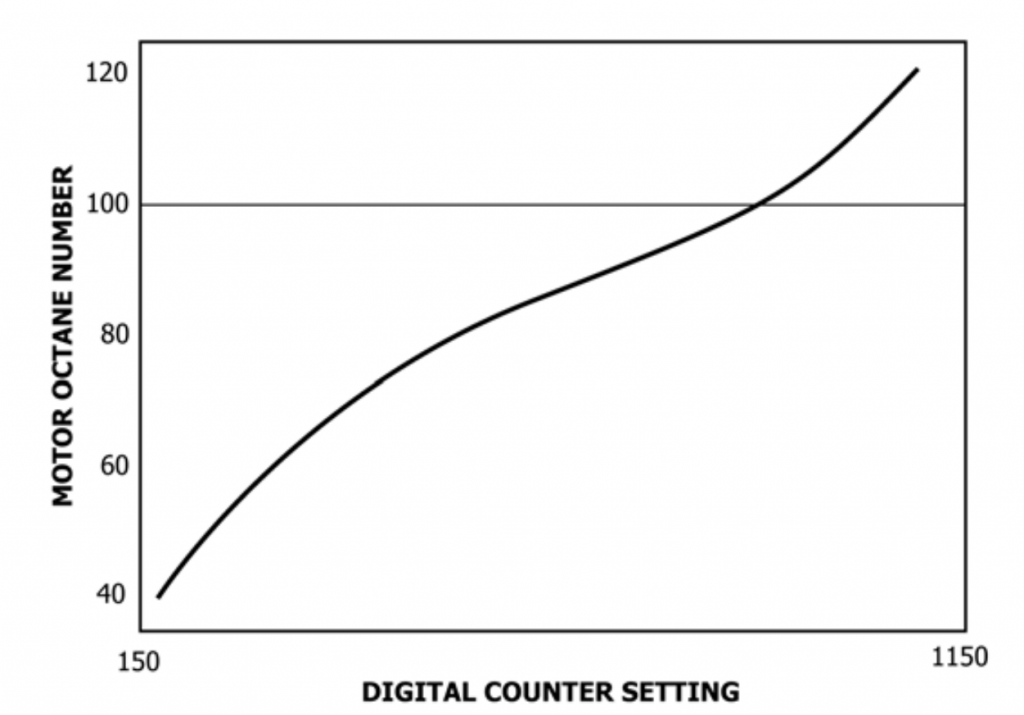

The RON/MON test method compares sample fuel to PRF blends at a selected knock level termed standard knock intensity. Guide tables of cylinder height versus octane number have been empirically determined using PRF blends. They are based on the concept that the knock intensity at all octane number values is constant as detected by the knock measuring instrumentation.

Octane number values determined by RON/MON test method are referenced to standard barometric pressure of 760 mm (29.92 in.Hg) changes in barometric pressure affect the level of knock. Because the density of the air consumed by the octane engine is altered. To compensate for a prevailing barometric pressure that is different from standard, the cylinder height is offset. So that the knock intensity will match that of an octane engine at standard barometric pressure.

For lower than standard barometric pressure conditions, the RON/MON octane engine cylinder height is changed to increase compression ratio and thus the knocking level.

For higher than standard barometric pressure conditions, the RON/MON octane engine cylinder height is changed to lower compression ratio. The changes in either digital counter reading or dial indicator reading are made to compensate for barometric pressure.