The Combination RON MON Octane Test Engine Unit FTC-M2 is equipped with a safety system to protect the whole unit. The safety system provides RON/MON test engine Automatic Shut-Down with the fault indications within 1 min. When any of follow conditions occurs on octane test unit: low oil pressure, loss of cooling water, high temperature of cooling water and short-circuit or electrical overload of the motor.

Coolant – Treated Water or a water/antifreeze mixture.

When the coolant temperature is too high, there will be a large number of water vapor from the coolant condenser top cap out. The RON/MON octane test engine unit will automatically stop within 1 min.

This situation may be caused by two reasons: 1) The cooling circulating water valve is not opened or the water pressure is not enough. 2) The coolant is not enough.

Check and turn on the cooling water to the coolant condenser.

Check and adjust to the cooling circulating water pressure to proper pressure on the water pressure regulator.

Check the coolant level on the condenser.

(Note: Engine Stopped and Cold-Treated water/coolant added to the cooling condenser-cylinder jacket to a level just observable in the bottom of the condenser sight glass will typically provide the controlling engine running and hot operating level.

Engine Running and Hot-Coolant level in the condenser sight glass shall be within 61 cm (60.4 in.) of the LEVEL HOT mark on the coolant condenser.)

Check and open the cooling water valve to the coolant condenser.

Check and adjust to the cooling circulating water pressure to proper pressure on the pressure regulator.

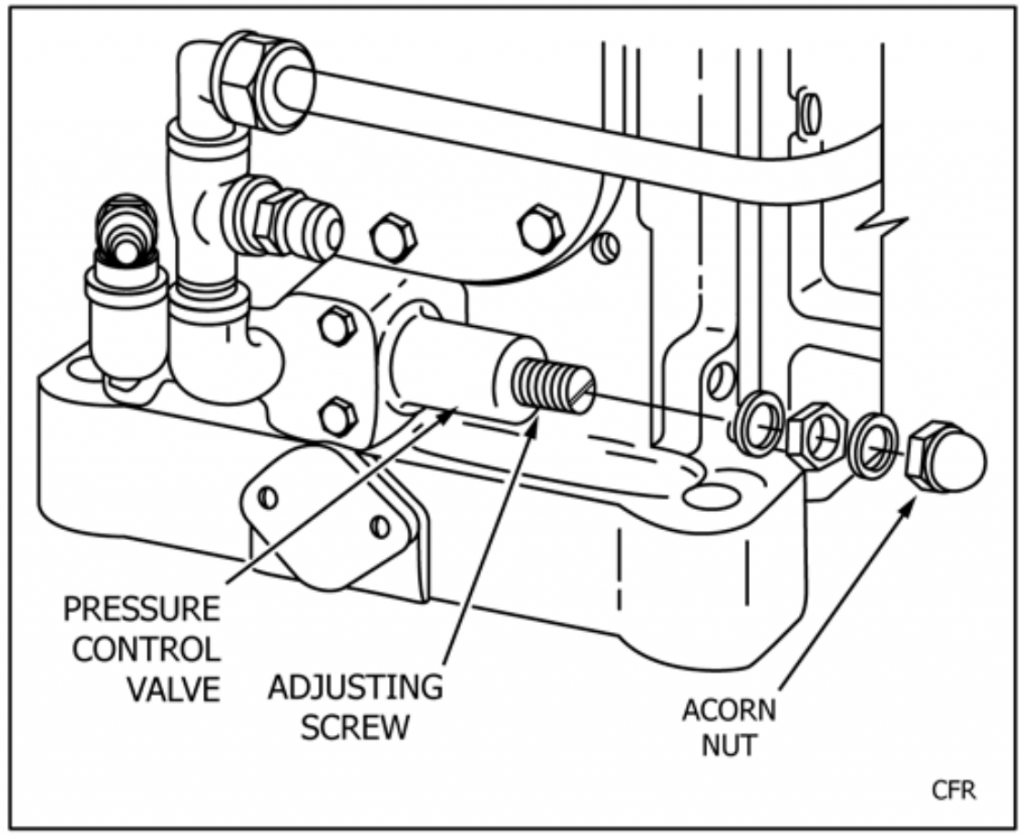

The oil pressure of the lubricating oil in the engine crankcase gallery is dependent on the setting of the pressure control valve located at the lower left side of the engine crankcase when viewed from in front of the engine.

Adjust the oil pressure with the engine hot and running, using the Oil Pressure Control Valve.

While observing the engine oil pressure gage, set the adjusting screw to obtain the specified 172 kPa to 207 kPa (25 psi to 30 psi) pressure.

Ask professional electrical engineer to check the power supply and grounding condition of octane test unit. After troubleshooting, turn on the overload protection and replace the fuse if necessary.