The factory-calibrated knock detonation meter of Octane Engines SINPAR FTC-M2 converts changes in combustion knock to a stable and accurate analog signal. The 0 to 100 division analog indicating meter that displays the knock intensity signal from the analog detonation meter. Digital knock signal adjustment effectively improves octane test accuracy and test efficiency.

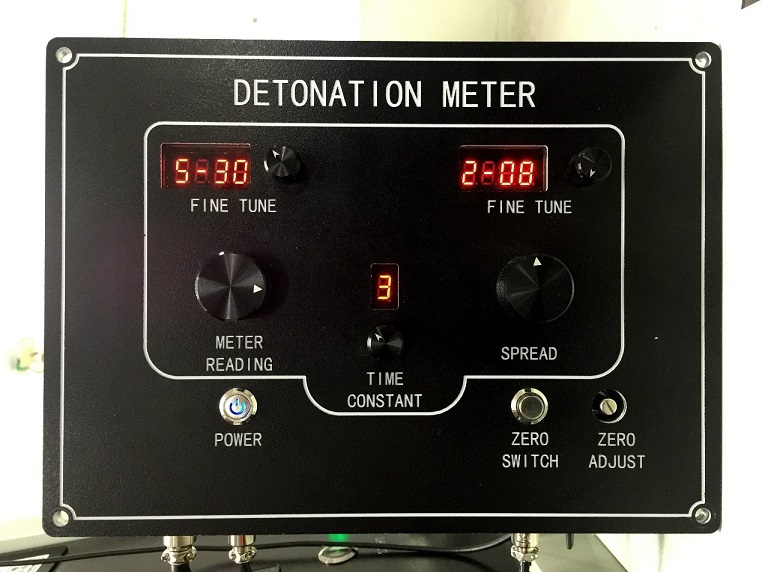

A “METER READING” Dial Assembly consisting of a coarse tuning ten position digital switch and a fine tuning ten position digital switch. The assembly provides control of a resistance network to adjust the output signal level for display on the knock-meter. The coarse tuning dial steps are in ten increments. The fine-tuning dial rotational range provides continuous variation of the signal level between each selected coarse tuning dial step and the next higher step.

A “SPREAD” Dial Assembly consisting of a coarse tuning ten position digital switch and a fine tuning ten position digital switch. The assembly provides control of a resistive network to adjust the sensitivity of the instrument, in terms of knock-meter divisions per octane number (K.I./O.N.). The dial numbers are relative in terms of K.I./O.N. because octane numbers vary in size with octane level. The coarse tuning dial steps are in ten increments. The fine-tuning dial rotational range provides continuous variation of the signal level between each selected coarse tuning dial step and the next higher step.

A “TIME CONSTANT” switch having seven positions. The switch controls how many cycles of engine combustion signal. These signals are integrated or averaged in the process of producing an average value of knock intensity. Position 0 averages the signals during a little over one second. And it is very responsive to knock variation but the knock-meter display is rather unstable as a result. Position 7 results in averaging the signals for approximately a 30 second period. And it is very unresponsive to changes in knock intensity and thus the knock-meter display becomes very stable. The knock-meter reading is on average the same for all time constant settings. But the stability of the reading varies from rather unstable at 0 to very stable at 7.

A “Zero Switch”. In the ON position, the input signal is short circuited so that the knock-meter instrument can be electrically zeroed.

A “Zero Adjustment” control potentiometer shaft is screwdriver adjustable and should only be changed, when the Zero Adjustment switch is in the ON position. So that the affect of the adjustment can be observed.